- Home

- Products

- Motor Driven Dosing Pumps

- Multifetric

Multifetric

Diaphragm & Piston type

The MultiFertic injection pump are heavy duty, high precision pumps for chemicals products and additives, made up of one driving module and 1 to 4 injection modules each having capacities of 25, 50, 100, 200, 300, and 500 l/h

The same injector can be connected several injection modules to apportion different products (INDEPENDENT INJECTION) or to increase the injection flow. By increasing the number of modules in the same injector, a higher flow regularity is obtained, whereby in the 4 modules model an actually continuous flow is obtained.

- Aluminium Die-cast body

- Maintenance free

- 10% to 100% Stroke Length Adjustment

- Up to four different modules can be added, which can be piston, diaphragm or both.

- Option for connect Variable Frequency Drive for providing 4-20 mA

MATERIAL OF CONSTRUCTION

Piston : Polyethylene or Ceramic (Piston pumps)

Cylinder : Polyethylene, Stainless steel or PVDF ( Piston pumps)

Diaphragm : Teflon (Direct Diaphram Pumps)

Specification

| MF 1 | ||||

Piston |

MODULE | FLOW | PRESSRE Bars | |

| l/h | GPH | |||

| MI1 -25 | 25 | 7 | 15 | |

| MI1 -50 | 50 | 13 | 15 | |

| MI1 -100 | 100 | 26 | 8 | |

| MI1 -150 | 159 | 39 | 5 | |

| MI1 -250 | 250 | 65 | 3 | |

| MF 2 | |||

| MODULE | FLOW | PRESSRE Bars | |

| l/h | GPH | ||

| MI2 -50 | 50 | 13 | 15 |

| MI2 -100 | 100 | 26 | 15 |

| MI2 -200 | 200 | 53 | 8 |

| MI2 -300 | 300 | 79 | 5 |

| MI2 -500 | 500 | 132 | 3 |

| MFD 1 | ||||

Membrane |

MODULE | FLOW | PRESSRE Bars | |

| l/h | GPH | |||

| MID1 -25 | 25 | 7 | 10 | |

| MID1 -50 | 50 | 13 | 10 | |

| MID1 -100 | 100 | 26 | 6 | |

| MID1 -150 | 150 | 39 | 4 | |

| MFD 2 | |||

| MODULE | FLOW | PRESSRE Bars | |

| l/h | GPH | ||

| MID2 -50 | 50 | 13 | 10 |

| MID2 -100 | 100 | 26 | 10 |

| MID2 -200 | 200 | 53 | 6 |

| MID2 -300 | 300 | 79 | 4 |

HYDRAULIC

Connections : Connections: M (3/4")

ELECTRICAL

Voltage : 230 / 400 Vac 3ph 50/60Hz, 110/230 Vac 1ph 50/60Hz, 12/24Vdc

Power : 0.37 Kw (0.5 Hp)

Protection : IP55 clause F

MATERIALS

Cylinder : P.P / AISI 316 / PVDF / PTFE

Diaphragm : Elastomer base reinforced with fiber and P.T.F.E clothing

Piston : Ceramic / PEUHMW

Sealing :FPM

Valve (body) : P.P / AISI 316 / PVDF / PTFE

Valve (ball) : glass / glass borosilicate / Ceramic

Block : Aluminium cast

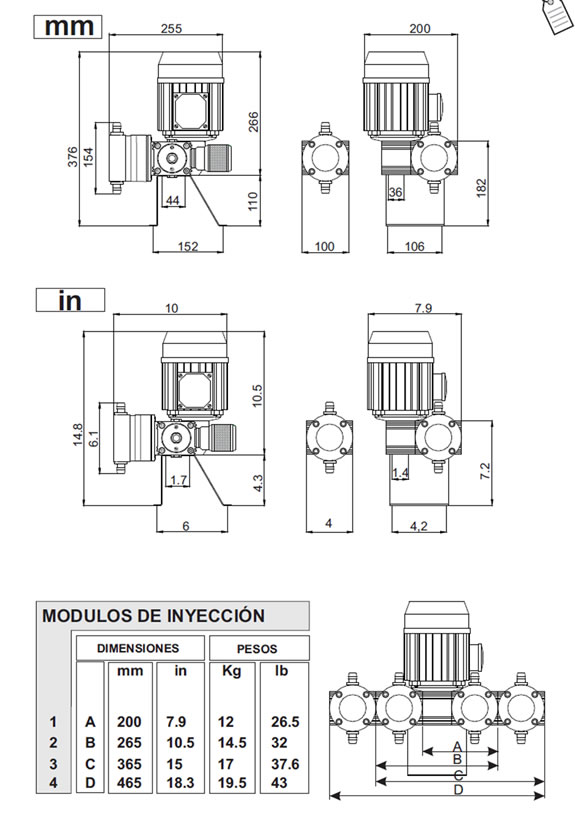

WEIGHT AND DIMENSIONS

Weight :

One module : 12 kg (26.5lb) Two modules: 14.5 kg (32lb)

Three modules : 17 kg (37.6lb)

Four modules : 19,5kg (43lb)