Manifolds & Chips

Whether your industry involves lots of plumbing jobs or any other manufacturing procedure, you cannot overlook the use of chips and manifolds. In particular, the combination of Manifolds & Chips for plumbing between pumps and valves may reduce flow-path length significantly.

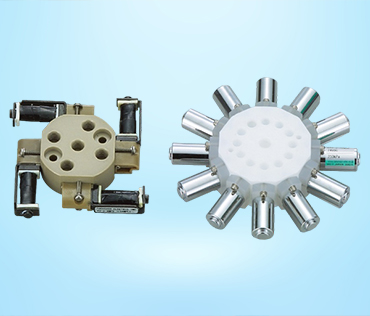

The features of Manifolds & Chips depend solely on the types used by manufacturing or plumbing companies. Accordingly, standard products consist of a few in-line manifolds mounted by a combination of valves. Standard devices have a relatively short delivery time but are available at the cheapest possible price. Chemical compatibility is the prime feature of standard manifolds, as they consist of PEEK to work as a high resistance to chemicals and work as a sealing material. These manifolds and chips also have standard inlets or common outlets with diverse port connections.

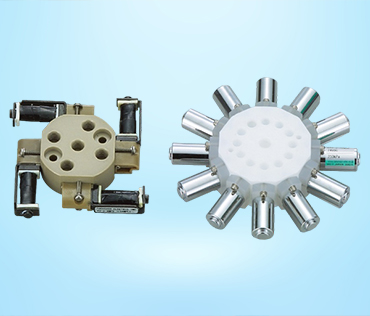

After that, custom manifolds reduce the internal volume minimization and plumbing activities. Moreover, custom manifolds may have channels with the minimum possible width. Custom products have relatively higher chemical compatibility as compared to standard products. These manifolds are available as a line or radial type based on customer needs and flow channel configuration possesses a standard outlet or inlet. Custom products may have a maximum of 190 valves. The last category is the bonded PTFE manifold.

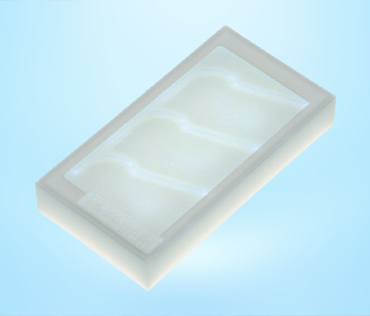

Manifolds & Chips are available with internal channels with pre-machineries over bonding surfaces. Bonded manifolds are compatible with varieties of fluids based on their outstanding resistance to chemicals. As the name itself, Bonded PTFE Manifolds & Chips allow perfect bonding with the help of a unique technique and without the use of any adhesive. Hence, the channels become free from any contamination problem. The chemical bonding method used in these chips and manifolds is reliable so that bonding surfaces unify properly to hardly distinguish the joining point.

Manifolds & Chips combination has wide applications in the plumbing between individual pumps and valves to cause compact installation of various components. Manifolds are also available in different variations based on industrial requirements, like manufacturing procedures and the material used. On the other hand, chips possess fine channels to give you competitive rates at the time of mass production in bulk quantities. For this, industries mainly use the method of bonding injection-molded resin films or plastic plates. A few chips have applications as disposable testing chips.

Sandur Fluid Controls Pvt. Ltd is one of the best Manifolds & Chips manufacturer, Manifolds & Chips exporter and Manifolds & Chips supplier in all over countires. Our company highly range to manufacturer of this Manifolds & Chips in builky. We are serve this Manifolds & Chips product universally. For more information you can contact our experts through our mobile number to assist in giving you more detailed information to meet your requirements. We Sandur Fluid Controls Pvt. Ltd are acclaimed to be the best in the field and give our competitors a tough fight with regards to our quality and rates! Time and again we have proved that we are better than the best !

We at Sandur Fluid Controls supply varieties of chips and manifolds to today's manufacturing companies. If you want details, check our website.

Specification

Standard Manifolds

FEATURES / CHARACTERISTICS

- The manifold is made from PEEK, giving it a high level of chemical resistance. FKM and FFKM (Perflouroelastomer) can be the sealing material.

- A flow channel configuration with a standard inlet or a common outlet is available. Please choose M6 or 1/4-28UNF for the port connections.

- According to your requirements, from 2 to 6 valves can be mounted on the manifold.

Custom Manifolds

FEATURES / CHARACTERISTICS

We provide our customers with components such as valves, pumps, etc., and design and manufacture Custom Manifolds to satisfy our customers' requirements. These manifolds contribute to a decrease in plumbing and minimization of the internal volume. Depending on the manufacturing technologies, a manifold with channels of a minimum width as narrow as 0.2 mm is also possible to provide. Please feel free to contact us for more information.

- There are compatible highly chemically inert materials such as PEEK, PPS, PTFE, etc. that are applicable for the manifold.

- Flow channel configurations with a standard inlet or outlet and a radial or line type are available according to customer requirements. Using a bonding technique, 3D flow channel configurations that the machining process cannot produce are possible.

- The number of mounted valves is selectable. We have the experience of manufacturing a manifold unit with 192 valves.

Bonded PTFE Manifold

FEATURES / CHARACTERISTICS

- This product is a 100% PTFE manifold, with the internal channels pre-machined on the bonding surfaces. Due to excellent chemical resistance, this product is compatible with a wide range of fluids.

- The integration of this valve manifold has been significantly increased, and freely curving channel designs beyond those made possible by conventional practices are now available.

- Bonding is successful using a unique technique that does not use adhesive, so the channels are contamination-free. The bonding method is highly reliable such that the bonding surfaces are to unify so well that the point of joining can be hardly distinguished.