Micro Pumps for Infusion / Drug Delivery Systems

Many times, hospitals, clinics, and pathology centers need small-size pumps to infuse or deliver drugs and insulin directly to patients. For this, healthcare experts buy or install Micro Pumps for Infusion / Drug Delivery Systems. The prime role of a micropump is to supply medicinal drugs at a relatively low rate of fluid flow.

Depending on specific medical requirements, companies supply four different types of models associated with Micro Pumps for Infusion / Drug Delivery Systems. The first is a tubing pump or peristaltic pump, which has a simple structure and does not allow any free flow. Besides, the motor rotation controls the volume to discharge from it. Secondly, we have thin-shaped piezoelectric diaphragm-type pumps, which consume low power and possess a wide range of flow rate control. The third model is a syringe pump driven by an electro-osmotic force and the last model is a shape memory alloy-operated infusion pump. Each of the models is lightweight, disposable, and comes with an actuator. A noticeable feature of an infusion pump is that it possesses a feedback system and a flow meter to measure fluid flow accurately and identify kinking or clogging issues.

Micro Pumps for Infusion / Drug Delivery Systems infuse small quantities of medication and vital nutrients into the body of a patient. The medications include antibiotics, hormone-related medicines, insulin, pain relievers, and chemotherapy medical drugs. Many micro pumps have a few other industrial applications, like delivery of glute in small amounts at the time of manufacturing medical products, and biomedical applications, like implanted or portable drug delivery systems. Besides, bio-inspired uses of infusion pumps are flexible electromagnetic pumping with the help of magnetorheological elastomer for the replacement of lymphatic vessels. Chemically powered infusion micropumps may make chemical sense to detect chemical warfare particles and hazards to the environment.

We at Sandur Fluid Controls Pvt. Ltd. have experts to supply varieties of microsize infusion pumps to clinics, hospitals, and other medical facilities. If you want details, look at our website.

Sandur Fluid Controls Pvt. Ltd has recently launched Micro Pumps for Infusion / Drug Delivery Systems that have been developed with the most advanced technologies of our times. Alongside simple usage, we have even ensured the safety of our customers. Compared to other machines, our Micro Pumps for Infusion / Drug Delivery Systems techniques are efficient in managing work-hour capacity and enhancing productivity.

Sandur Fluid Controls Pvt. Ltd is one of the best Micro Pumps for Infusion / Drug Delivery Systems manufacturer, Micro Pumps for Infusion / Drug Delivery Systems exporter and Micro Pumps for Infusion / Drug Delivery Systems supplier in all over countires. Our company highly range to manufacturer of this Micro Pumps for Infusion / Drug Delivery Systems in builky. We are serve this Micro Pumps for Infusion / Drug Delivery Systems product universally. For more information you can contact our experts through our mobile number to assist in giving you more detailed information to meet your requirements. We Sandur Fluid Controls Pvt. Ltd are acclaimed to be the best in the field and give our competitors a tough fight with regards to our quality and rates! Time and again we have proved that we are better than the best !

4 Basic Structures and Main Features

- Tubing Pumps (Peristaltic Pumps)

Simple structure. Discharge volume control by the rotation of the motor. No free flow. - Piezoelectric Diaphragm Pumps

Thin shape, low power consumption, and wide flow rate control range. - Electro-osmotic Flow Driven Micro Syringe Pump

The syringe also works as a drug reservoir. Ultra-low power consumption. High discharge pressure. - Shape Memory Alloy Driven Micro Metering Pump

Disposable, including the actuator. Thin and ultra-lightweight.

Specification

Planar Tubing Pumps (Chip Pumps)

In contrast to other companies' products, our pump differs by storing the tubing in a chip that contains magnets so that the chip can be easily attached to and detached from the motor unit. This method makes the replacement of tubing very easy. The video below shows how it all works.

We can offer either a stepper motor for high precision flow control or an economical DC motor that consumes less power. When the motor stops, the tubing is closed by a roller, so a free flow (a small amount of leakage due to a head difference) does not occur.

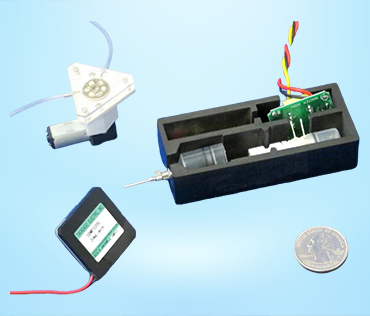

The top image shown to the side is of our smallest tubing pump, weighing only 5 g. The flow per rotation is 2 μL.

The lower image to the side is a product with a maximum flow rate of 200 μL/min. Customization to further increase the flow is possible.

Piezoelectric Diaphragm Pumps (Piezo Pumps)

This product uses a unique pump called an "Electro-osmotic pump" for the driving unit, which slowly discharges a drug stored in a microsyringe without pulsation. Since it consumes little power, miniaturizing the battery is possible. One of its features is that it can inject a drug at a higher pressure than other pumps. Please visit the link below to see how it works.

Electro-osmotic Flow Driven Micro Syringe Pump

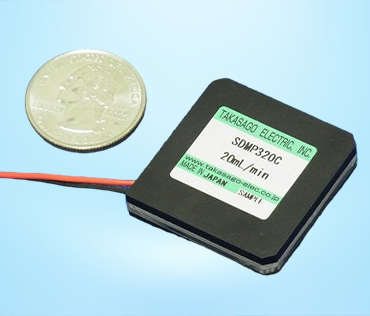

A magnet attached the wetted part to the piezoelectric driving unit and is easy to replace. The product in the picture is just 6.9 mm and 13 g. The piezo pump is ideal for feedback control since its flow rate is finely adjustable by the voltage and the frequency.

Shape Memory Alloy Driven Metering Pump

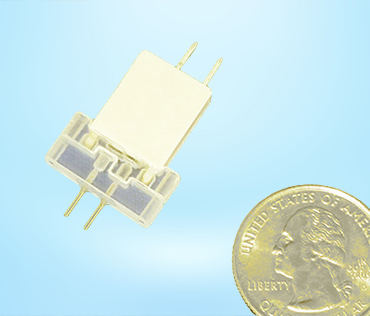

This pump dispenses about 0.9 μL of liquid per shot by shrinking a shape memory alloy wire. This feature makes it the most economical among the four basic structures because it does not use a motor or more expensive actuators. The expectation is that the user will replace the entire pump after each use. The number of pumping shots controls the amount of injection. The product in this picture is just 4 mm and 1.7 g. This pump is also lightweight, a beneficial feature—no free flow.